5 Questions To Ask When a Valve Isn’t Working

Before we troubleshoot, we ask these every time.

When a valve isn’t doing what it’s supposed to, your first instinct might be to get to the valve and start adjusting, turning, screwing and beating on things, but here’s the reality: without a clear understanding of the valve’s function, current state, and role in the broader system, your intervention might actually make things worse.

We take troubleshooting calls all the time to help operators identify issues and make smart, informed decisions with their valves. At the heart of good troubleshooting is clarity. We want to understand exactly what’s going on so we can guide you to the right solution without wasting time, effort, or money.

Every time someone calls us about a valve that "isn’t working," we start by asking the same five questions. These foundational questions help us figure out what the valve should be doing, what it’s actually doing, and what might’ve changed.

Even better? When you already know the answers to some of these questions before you call, it sets us up to help you get to the right fix even faster. Let’s walk through them.

1. What is the size and model number of the valve?

This is always the first question.

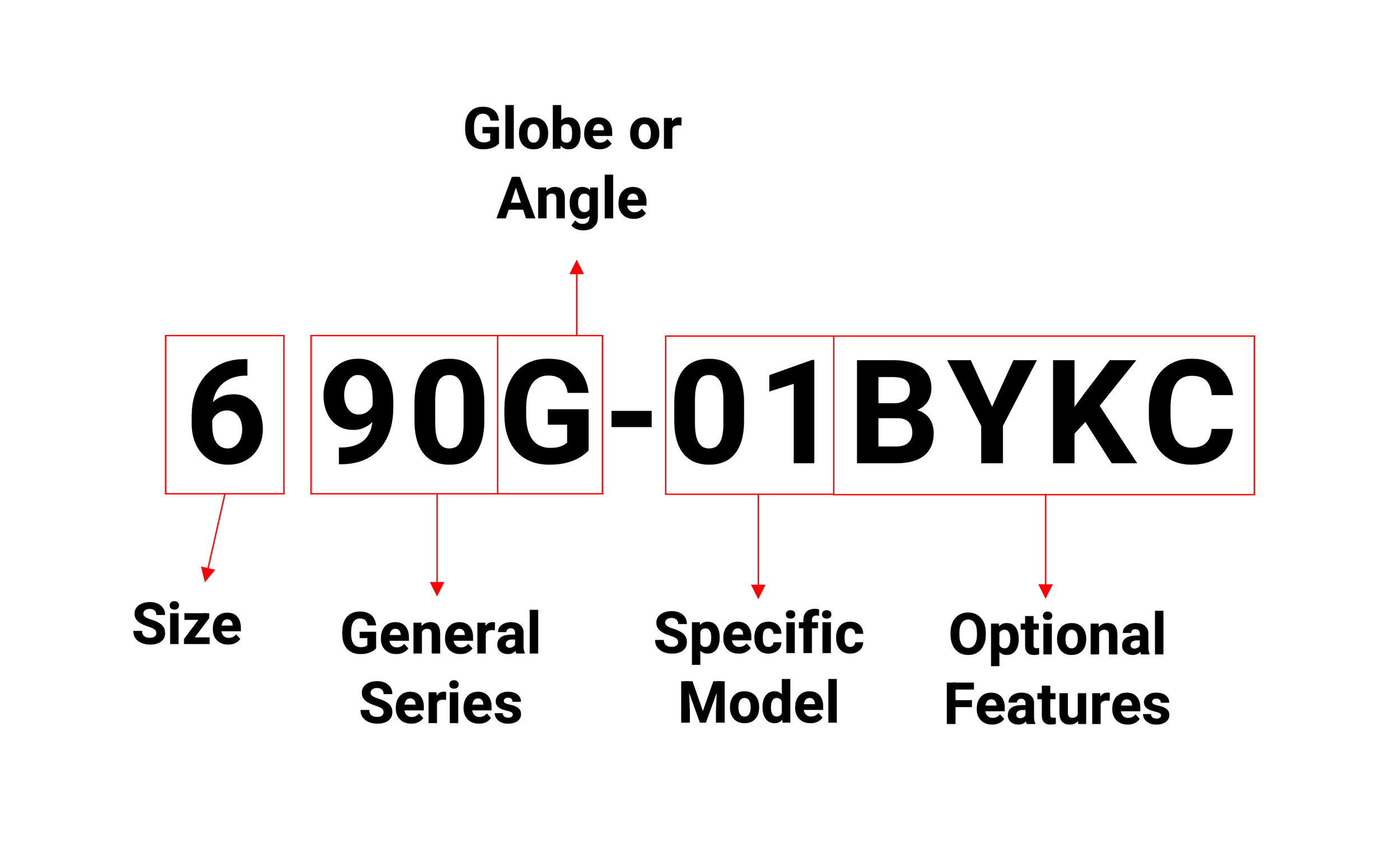

Every Cla-Val was designed to perform one or more of thousands of possible functions. The model number is a combination of numbers and letters (e.g. 6 90G-01BYKC) that gives us information about the specific job that the valve in question was designed to do. Without this information, we’re flying blind.

Cla-Val Model Numbering System

You can usually find the model number on a brass tag:

3” and larger flanged valves: Tag is on the inlet flange.

Smaller valves: It’s riveted to the side of the valve body.

Tag on inlet flange; tag on side of valve body

If the tag is missing or worn out, snap a few photos of the entire valve and pilot system—one from each side works best. We can typically identify a valve’s size and model number with relative certainty from these kinds of pictures.

Take pictures on both sides of valve with all pilot system components in view

2. What indicates to you that the valve isn’t working?

In plain terms: What’s the problem?

We want to know what’s changed. How is the valve behaving differently than usual? What are the signs that told you something’s off?

Examples of symptoms we often hear:

Pressure is too high (or too low)

The valve is shut but should be open

The valve is open but should be shut

You’re seeing leaks in the pilot system

Knowing what clued you in to the problem helps us start building the story of what’s happening.

3. What is the valve supposed to be doing?

Yes, this is a different question from the last one.

Here, we’re asking: What does normal operation look like? What are the intended set points or pressures? Do you have those written down somewhere?

Some common places to find that info:

Holy grail / infamous PRV binder buried deep below the water department office

Brain of the lead operator who retired 3 years ago

Laminated cards or notes stored near the valve

Logged in Cla-Val’s Link2Valves platform (if you’re using it)

Cimco-GC Systems service records (we might already have this info if we’ve worked with you before)

Knowing what the valve should be doing makes it way easier to figure out what’s gone wrong.

Cla-Val’s Link2Valves Asset Management Platform

4. What is the valve doing right now? Have you changed anything?

This one’s about the valve’s current state.

Is the valve in operation? Is it isolated? Have you shut it off? What are the current inlet and outlet pressures?

We’re trying to understand whether the issue is ongoing, if you've already made adjustments, and what’s happening in real time. Maybe you’re seeing lower pressure than normal, but the valve is still online and flowing. Maybe the pressures are high, and you shut off the valve. That gives us a much clearer direction for further investigation.

5. Has anything changed in the broader system?

Sometimes it’s not the valve’s fault.

Valves don’t operate in isolation, they’re part of a bigger system as a whole. Changes upstream or downstream can cause a valve to act up, even if it’s in perfect working order.

We’ll want to know:

Has there been new construction nearby?

Any recent repairs? Main breaks? Line flushing?

Has a new tank, well, or zone been added?

We’ve seen everything from rocks to rags to entire 2x4s get lodged in a system after a repair or install. It happens!

Any of these scenarios can impact system pressures and dynamics. So even if the valve looks suspicious, sometimes it’s just reacting to something else.

One More Thing: Keep Good Records

We can’t stress this enough. Accurate, up-to-date records are incredibly helpful when problems arise. When you’re in the middle of troubleshooting, the last thing you want is to be digging through old notebooks or calling around to figure out what the pressures were supposed to be.

Proactive tracking, like keeping pressure set points, zone info, and maintenance history handy can make all the difference. This is where Link2Valves really shines. (It’s free, and we’ll help you get set up if you want.)

Cla-Val’s Link2Valves Asset Management Platform

Conclusion

Before we start running any tests or taking apart your valve, we need answers to these five questions.

They help us figure out:

Is the valve malfunctioning—or is it responding appropriately to a system issue?

Is the problem inside the valve body—or something external, like the pilot system?

Here’s a great example: If you see a relief valve going off, don’t immediately shut it down. It might actually be doing exactly what it’s supposed to…relieving high pressure. If you turn it off, that pressure builds up in your system, and now you’ve got a whole new set of problems (think: burst mains or damaged water heaters).

Again, it’s not always the valve’s fault. But once we have the right info, we can help you figure out whether to adjust the valve, repair it, or look elsewhere in the system.

Need Help? We’re Here.

If your Cla-Val isn’t working the way it should, or you’re not even sure what it should be doing—give us a call. We’ll talk through these questions with you and help you troubleshoot step by step.

Your work keeps water flowing, and we’re here to back you up every step of the way!

Beau Swet

Service Department/Operations Manager