Under Pressure: Engineering Altitude Valves for Real-World Conditions

Altitude valves play a key role in water system design–primarily ensuring tanks don’t overflow! The simplest way to know whether you need an altitude valve in a particular application is to answer this question: “Would the tank overflow without one?

However, designing the right altitude valve is not as straightforward. Open air water storage reservoirs that connect to pressurized pipelines create interesting hydraulic scenarios and challenges related to pressures. And since storage tanks hold our emergency water supplies, getting it right is crucial.

To get your next altitude valve application design right, start with these two foundational questions:

Is there enough pressure?

Is there too much pressure (or flows)?

Before we dive in, keep in mind this isn’t an exhaustive guide to every altitude valve scenario. Instead, we’ll be focusing on common pressure-related challenges and some of the options for addressing them. We’re here to support you, so don’t hesitate to give us a call to discuss the specifics of your next altitude valve design!

Question #1: Is there enough pressure?

Storage tanks are often situated at the edge of a water system or at a high point in the terrain where pressure can be scarce. Here are a few things to check if you don’t have a lot of pressure:

Is there enough pressure to fill the tank?

Believe it or not, we have seen tank designs where the available pressure is not actually sufficient to fully fill the tank. Each foot of tank elevation equates to .433 psi of pressure needed. If the pressure in the system at the water tank is only 10 psi, you can’t fill a 30 foot tall tank.

That means you’ll either need a shorter tank, a pump station to boost the pressure, or to relocate the tank to a lower elevation.

Is there enough pressure for a control valve to work?

Diaphragm actuated control valves use line pressure to operate. For a non-modulating altitude valve, we recommend a minimum of 5 psi of differential pressure for proper operation. In addition, the valve needs at least 3-4 psi of total pressure to even open. Without enough pressure, the valve may close prematurely and prevent the tank from fully filling.

Also, if you add modulating controls to the valve, such as pressure or flow, or if you add a check feature, the recommended minimum differential pressure jumps to 10 psi! Keep that in mind when selecting functionality and features.

Val-Matic Swing Flex Valve: If you do not have much pressure and want a check feature on the line, we recommend using a separate check valve to allow proper altitude valve functionality.

Is there enough pressure to flow back through the valve?

A standard altitude valve controls flow into a tank, but configurations that allow for two-way flow are also available. When inlet pressure is greater than tank pressure the valve flows to fill the tank, and when tank pressure is greater than inlet pressure the two-way flow valve allows flow in reverse out of the tank. As pointed out above, a diaphragm actuated control valve requires pressure differential to operate and at least 3-4 psi to open. If you are wanting to flow out the control valve, does the tank have enough height to keep the valve open? 3-4 psi equates to 7-9 feet of water height. Would a two-way altitude valve lock water in the tank during an emergency?

A way to solve this is to add a bypass around the control valve with a check valve that allows flow out of the tank, but not in. Most check valves have much lower head loss and cracking pressure to operate than a diaphragm actuation control valve. For example, a Swingflex check valve from Val-Matic only requires .25 psi to open.

QUESTION #2: Is there too much pressure?

For tanks and reservoirs located inside a distribution zone, the pressure situation can be quite different. You may find considerable pressure differences between the system and the tank. Here’s what to look at if you have a lot of pressure:

What would happen if my altitude valve fully opened?

A standard altitude valve is a non-modulating valve, meaning it’s either fully open or fully closed. So when the tank level is low, the valve will fully open to fill the tank, and then fully closes once full. What would happen with high pressure differential if your valve fully opened?

For example, let’s say you have a 25-foot tall tank with an 8” altitude valve inside a distribution zone that’s normally pressurized to 60 psi. 25 feet of water creates only 10.8 psi of pressure–and that’s assuming the tank is completely full. If the tank is only partially full the pressure would be less. Therefore, your altitude valve could have 60 to 50 psi of differential pressure.

Given this scenario, if the 8” altitude valve fully opened with 60 psi of inlet pressure and 10.8 psi or less of outlet pressure, either:

A) The valve would flow a lot – like 5,000 gpm with velocities above 30 feet per second before head loss caps the valve’s flow, or:

B) System pressure would drop like a rock because the system cannot supply enough flow. The pressure would drop until the flow rate across the valve decreases to the point where the system can keep up. This could be substantial.

Neither option is a good situation for the distribution zone or the valve. With option A we don’t recommend flowing that much through an altitude valve. We recommend keeping flow velocities below 20 feet per second through the valve. High velocities can lead to premature wear and poor valve function. With option B, how much will the system pressure drop? Do you want system pressure dropping every time you fill your tank? What if there’s an emergency or a fire while you’re filling?

One way to solve excessive flows and pressure drops is to size the valve smaller so the valve has less capacity and naturally flows less, easing the effect on the system. For example, in the above scenario if you used a 4” valve instead of an 8” valve, the resulting flow rate with 60 psi of inlet pressure and 10.8 psi of outlet pressure would be about 1,300 gpm, instead of 5,000 gpm. The system may be able to handle that high of a flow rate without adverse effects to system pressure. However, that would still result in flow rates of over 30 feet/second in the 4” valve.

Another important consideration–cavitation.

Will my valve be in cavitation damaging conditions?

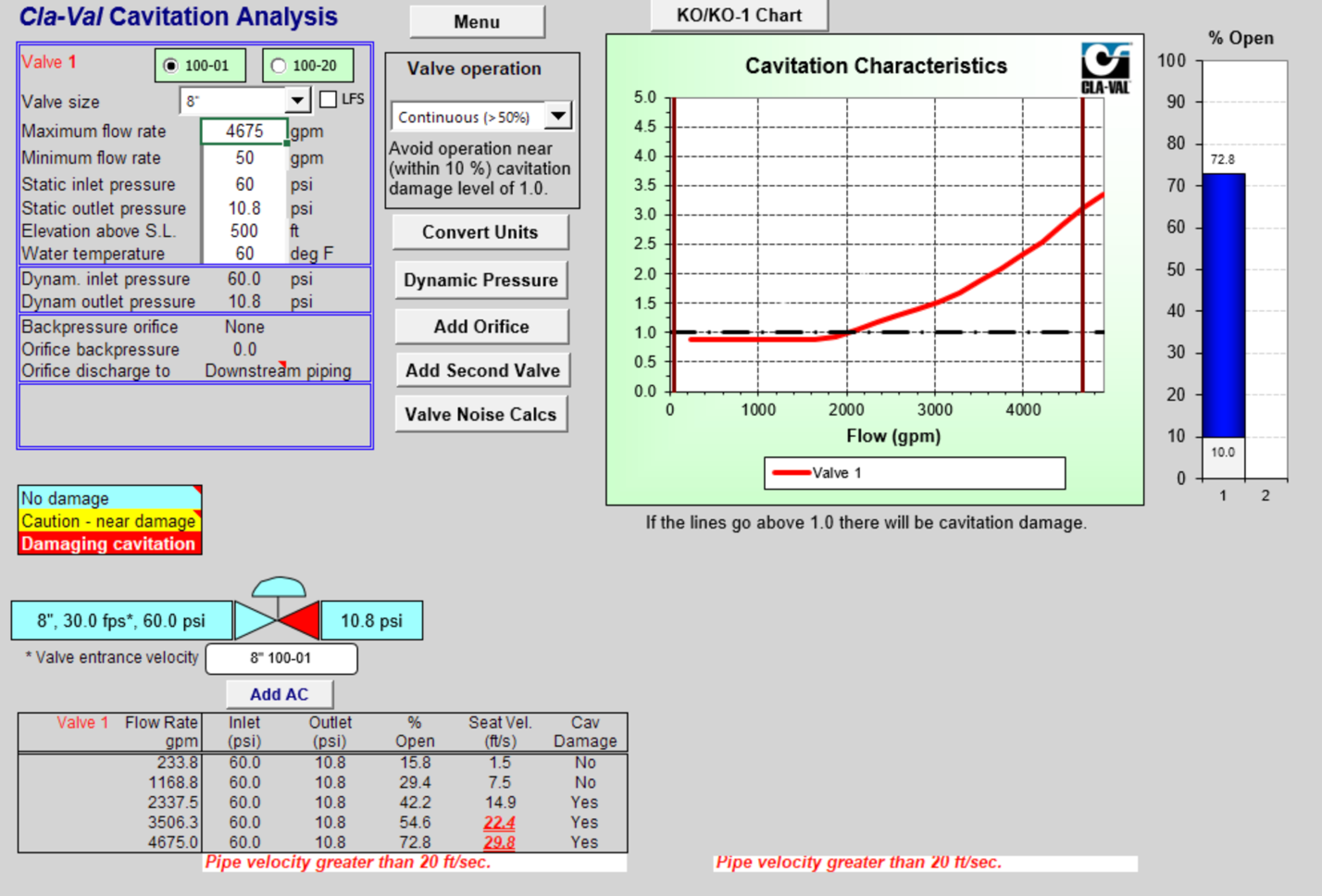

The cavitation scenario for a valve depends on pressures and flows. Below is a cavitation analysis for our example 8” valve, with 60 psi of inlet pressure and 10.8 psi of outlet pressure:

Cavitation Analysis of our example 8” valve, with 60 psi of inlet pressure and 10.8 psi of outlet pressure

The cavitation situation is fine until flow rates exceed 1,800 gpm – at which point the valve enters cavitation damaging conditions. And it only gets worse as flow rates increase. Not only would the valve be flowing above recommended velocities, but it would be in cavitation damaging conditions. This would likely result in pipeline vibrations, loud noise, and cavitation damage on the inside of the valve causing premature valve failure.

Note, this is assuming a full tank. If the tank is not full the cavitation situation gets even worse!

Fortunately, Cla-Val has a solution with KO anti-cavitation trim. KO trim replaces the seat and disc guide and protects the valve from cavitation damage. KO trim also creates more head loss through the valve which can restrict flow depending on the differential. For the above 8” valve with 60 psi of inlet pressure and 10 psi of outlet pressure, the valve would have a maximum flow capacity of about 2,300 gpm, or 15 feet per second. This could be useful to not only protect the valve from cavitation damage but also limit flow.

Other options for alleviating excessive flows or pressure fluctuations:

Altitude Valve with Flow Control

Instead of relying on the head loss of a fully open valve to limit flow, you could just add flow control to the valve. We can accomplish this hydraulically with a differential pilot and orifice plate or electronically with dual solenoids. The valve would still open and close to fill the tank, but instead of fully opening the valve would open only as much as needed to allow the desired flow rate. This could be useful for limiting flow rates, velocities, and even keeping a valve out of cavitation damaging conditions.Altitude Valve with Pressure Sustaining Control

Another approach to modifying an altitude valve to preserve system pressure would be to add a pressure sustaining control. This would usually be a hydraulic pilot that senses upstream pressure, but could also be accomplished with dual solenoid electronic controls. The valve would open and close to fill the tank, but when filling the tank the valve would look at upstream pressure and only open as much as possible without lowering upstream pressure below the pressure sustaining set point. The pressure sustaining function would not be controlling for a particular flow, just upstream pressure. The valve would flow as much as the system could provide while still maintaining system pressure.The benefit with pressure sustaining is that the valve will react to other demands in the zone. If there was an emergency that dropped system pressure (such as a fire), the altitude valve with pressure sustaining would react and limit flow or close and stop filling until pressure recovered.

Note, pressure sustaining controls only limit flow through the valve if upstream pressure drops. If the system is big enough to supply, or if pumps kick on to keep pressures up, a pressure sustaining control would not do anything.

Altitude Valve with Flow Control and Pressure Sustaining Control

We could also combine all the above for an altitude valve that–when filling–controls for a flow rate and a minimum upstream pressure. This valve would open to fill the tank and either flow a maximum flow rate or maintain a minimum upstream pressure–whichever the valve hits first. That way you could have a specific flow cap (Sustaining will flow as much as is available) and the valve would be sensitive to other demands in the system (flow rate does not see upstream pressure). With diaphragm actuated control valves

An altitude valve with electronic flow control, pressure sustaining, pressure reducing with check feature in Puget Sound area.

LEAN ON OUR TEAM

Knowing whether you need an altitude valve is the easy part. Designing the right one takes precision, insight, and a deep understanding of system dynamics. Whether you’re dealing with low pressures or high, there are smart configuration options that can protect your system and ensure critical water resources are available when they’re needed most.

Your work matters. Thoughtful engineering protects water infrastructure and safeguards the communities that depend on it. If you’re in the thick of pressures, flow rates, and elevation calculations you’re not alone. This kind of technical challenge is exactly what we love helping engineers solve.

Lean on Cimco-GC Systems for support. Our team is here to help you make confident, informed decisions about your altitude valve applications.

Robert Velasquez

Robert currently works in Engineering Support and Technical Sales - specializing in Cla-Val design, quoting and specifications. Nothing captures his imagination quite like water system and valve design. When he’s not finding solutions to complex application challenges, he enjoys training operators and getting back out in the field with the service team.